Effects of Wrong Alignment on Belt Life are mostly neglected by fitter. We with last 40 years history in Belting Business in Pakistan, most of the time, we face short belt life with no compromise on quality. We at Al-Haq Traders got confused and often talked to our Parent companies for this. We were advised by our parent companies in 1990s that helped us to know much of mechanical faults that reduces the belt productivity and life.

Effects of Wrong Alignment on Belt Life

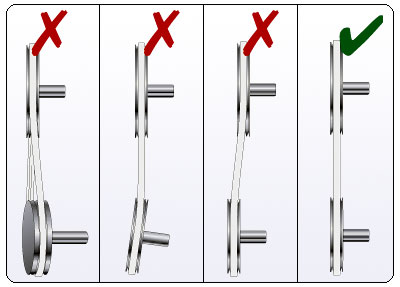

If a belt is wrongly aligned to Shafts or with pulleys it may result many damages to machine and man too.

Shortens belt life

If a belt life is supposed to be 6 months or 1 year. It can be in hours or days.

Damages Bearings/Bushes

Yes. A wrongly aligned belt is burden on bearings or bushes, it takes more load.

Reading: “Why Textile is going down in Pakistan“

More power Consumption

Often we drive a car. If we accelerate and break in the same, what happens? the same is here.

Increases Cost of production

Repeatedly belt changing, bearing installation, bushes, high electricity bills, over times and other factors include cost to production that minimizes profit percentage.

Small grips on shafts reduces machine rpm

Misaligned belts do not have full grip for driving shafts. Less grip results in lowering machine rpm. Required production quality goals or production volumes are not achieved.

More chances to Machine Accident

Obviously, shafts cracks, belt cracks, broken bearings or belts sometimes can stuck somewhere in machine. So why to risk?

A belt should always be aligned straight for better belt life, low-cost, continuity in productions, and smooth machine run. Top belting companies are failed in case of misaligned belt, suppose Niita a Korean manufacturer with Forbo Germany technology can do nothing for better life on wrongly aligned belt.